Meetscrafts 16oz 1:1 Tear Resistant Food Safe Platinum Cure Liquid Silicone Rubber for Mold Making Kit

-

Estimated Delivery:Dec 06 - Dec 10

Meetscrafts 16oz 1:1 Tear Resistant Food Safe Platinum Cure Liquid Silicone Rubber for Mold Making Kit

Meetscrafts 16oz 1:1 Tear Resistant Food Safe Platinum Cure Liquid Silicone Rubber is a high-quality, non-toxic platinum-cure liquid silicone rubber designed for mold making. With exceptional tear strength and flexibility, it accurately replicates intricate details and is ideal for casting materials such as polyurethane, epoxy resin, polyester resin, wax, and more, ensuring high-quality results.

This silicone rubber features a simple 1:1 mixing ratio by volume, making it easy to use without the need for weighing scales. Its low viscosity allows it to flow smoothly into even the finest textures, crevices, and intricate shapes of your prototype, ensuring every detail is captured accurately. Once cured, the silicone rubber forms a soft yet durable mold that is highly tear-resistant and exhibits very low long-term shrinkage, making it ideal for high-precision mold production.

Features:

-

1:1 Mixing Ratio: Easy-to-use 1:1 mix by volume, no weighing scale required, ensuring accurate curing.

-

Tear Resistance: Excellent tear strength ensures molds are durable and can withstand repeated use.

-

Low Shrinkage: Very low long-term shrinkage, ensuring molds maintain their shape and accuracy over time.

-

Food Safe: Suitable for food-grade mold making, ideal for the culinary industry.

-

Translucent Color: Clear silicone allows for creative color effects when mixed with silicone pigments or effect powders.

-

Flexibility & Precision: Excellent fluidity ensures smooth flow into fine textures and intricate details, perfect for precision mold making.

-

No Vacuum Degassing: Most applications do not require vacuum degassing, making it easier to work with.

Specifications:

| Mixing Ratio | 1:1 (A:B by volume) |

| Shore A Hardness | 10A |

| Pot Life | 50 minutes |

| Cure Time | 4 hours |

| Color | Translucent |

| Applicable Materials | Polyurethane, Epoxy Resin, Polyester Resin, Wax, etc. |

| Additional Options | Create endless color effects with silicone pigments or effect powders |

Product Applications:

-

Mold Making: Ideal for creating high-precision molds for various applications, ensuring detailed reproduction of prototypes.

-

Food-Safe Molds: Perfect for food-grade mold making, compliant with food safety standards.

-

Art & Jewelry Making: Suitable for art, jewelry, and craft mold making, capturing every fine detail.

-

Prototyping: Great for rapid prototyping, ensuring accurate replication of fine details and shapes.

-

DIY Projects: Ideal for DIY enthusiasts, providing flexibility and high precision for home projects.

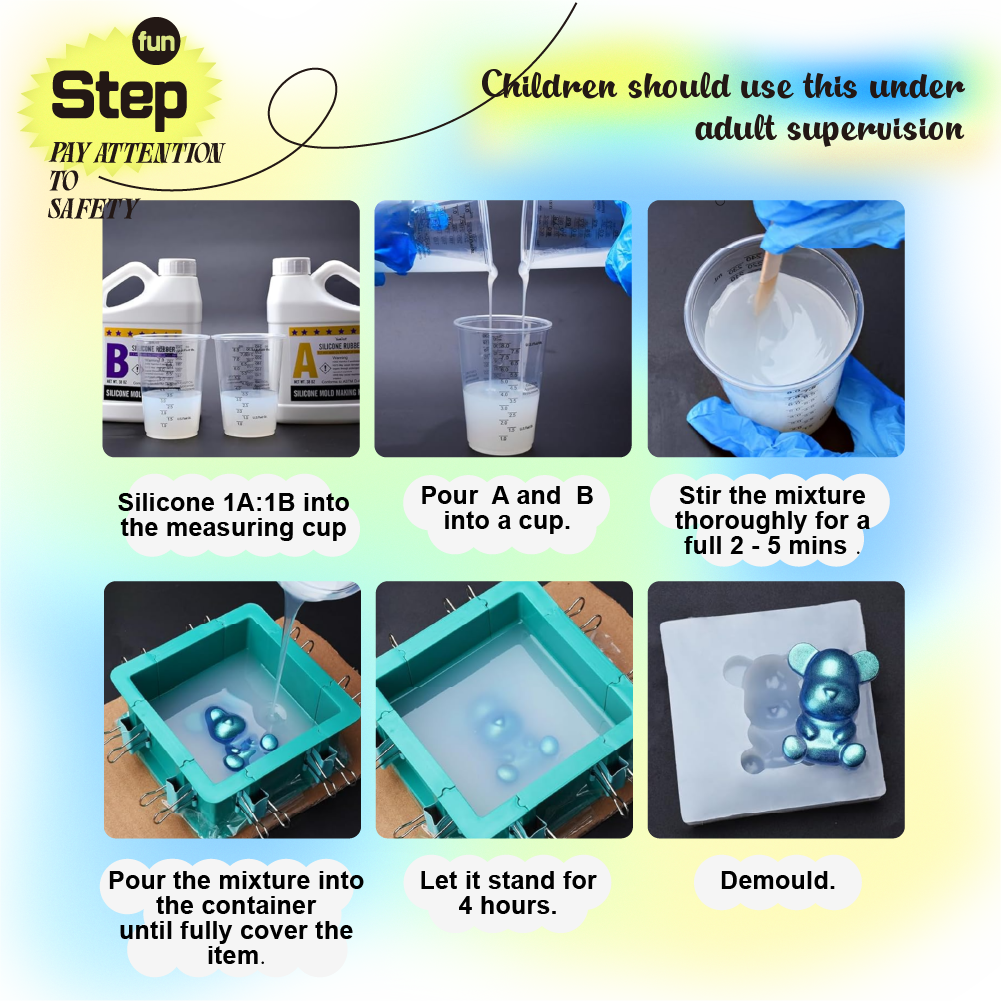

How to Use:

-

Ensure Safety:Use the product in a well-ventilated area to ensure proper air circulation. Always wear safety glasses, long sleeves, and rubber gloves while handling the silicone. Vinyl gloves are recommended (avoid latex gloves, as they can interfere with the curing process of the silicone).

-

Prepare Materials:Measure out parts A and B in a 1:1 ratio by volume and pour them into a measuring cup. Ensure the ratio is accurate for proper curing.

-

Thoroughly Stir the Mixture:After pouring parts A and B into the measuring cup, stir the mixture thoroughly for 3 to 5 minutes to ensure complete blending and remove any bubbles.

-

Pour into Mold:Pour the thoroughly mixed silicone into your mold, making sure it fully covers the item and reaches all details of the prototype.

-

Cure and Wait:Allow the silicone mixture to cure in the mold for 6 to 12 hours, depending on the environmental temperature and the amount of material used. Ensure it is fully cured before demolding.

-

Demold:Once curing is complete, carefully remove the mold. Check for accurate detail replication to ensure the mold has captured every aspect of the prototype.